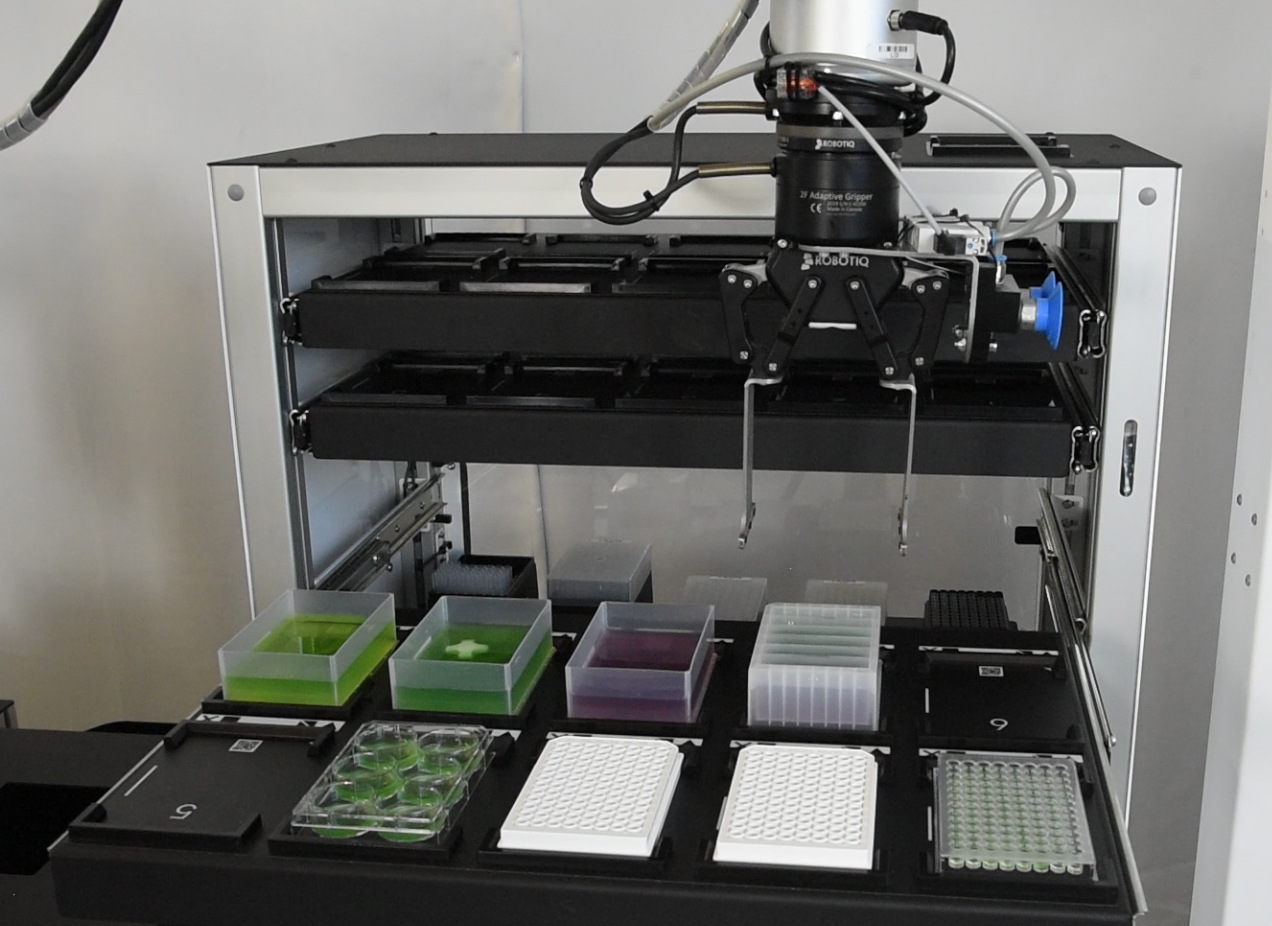

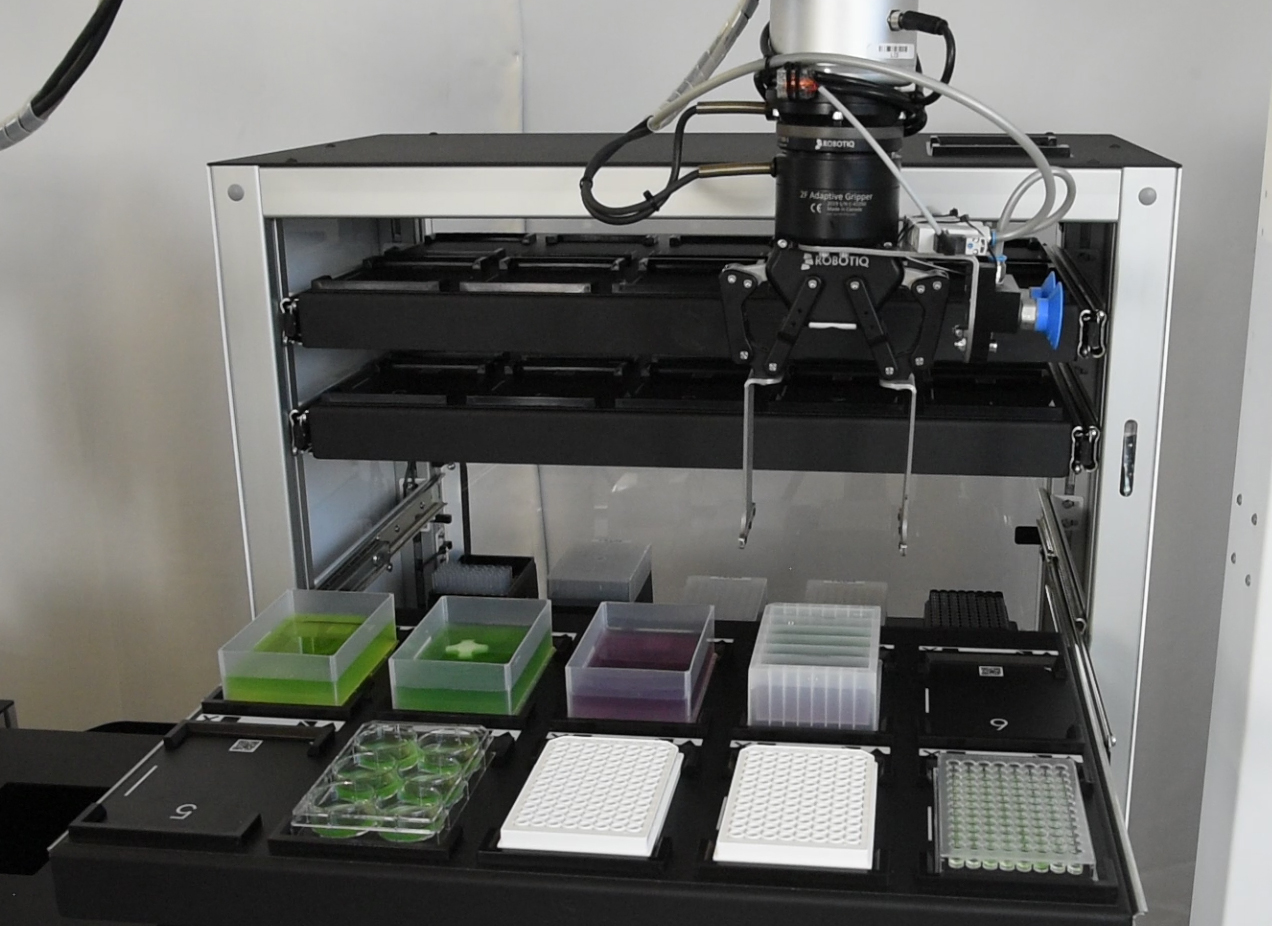

AlgaeScreen is integrated automatic robotic solution for screening and phenotyping of algal and cyanobacterial strains and for cultivation of them. Microplates are transported by robotic arm from controlled shaked incubators towards imaging stations and liquid handling station. Data are acquired from bottom side of microplates.

- Multiple imaging sensors for comprehensive analysis.

- Operates 24/7 for continuous monitoring and experimentation.

- Equipped with a durable robotic arm for sample transport.

- Includes a cultivation box for maintaining optimal growth conditions.

- Features an automatic sample preparation system for precise pipetting.

- Utilizes an open database structure for data storage.

- Comprehensive software package for system control and data analysis.

- Scalable and customizable to accommodate different needs.

- Compatible with ANSI-SBS Footprint labware.

Life science, Biotech, Medical

AlgaeScreen is integrated automatic robotic solution for screening and phenotyping of algal and cyanobacterial strains and for cultivation of them. Samples are caried by autonomous robotic arm in microplates (6 well, 24 well, 96 well) from controlled-environment growth incubators towards imaging stations and liquid handling station. AlgaeScreen is developed to be placed in laboratory or growth capsule.

The system consist of robotic operated stations: cultivation incubators, imaging stations, sample preparation station.

Area for manual loading of plates is integrated and allows user to run measurement while another samples are growing inside incubators. AlgaeScreen system is highly modular system and can expanded be other custom-developed station (UV mutagenesis station..).

Liquid handling station is powerfull high-precision tool that automatically pipets solutes to a defined location and is also equipped with magnetic stirrer that ensures homogenous distribution of inoculum.

Samples in microplates can be stored in shaked incubators with controlled environment from 15°C to 30°C. These AlgaeHotels have the capacity for 48 plates (24 well or 96 well) and can be exposed to light intensity up to 1500 µmol.m-2. s-1.

Software control

Comprehensive software package has been developed for system control, data acquisition, image analysis and database configuration. User friendly graphical interface is designed to control all hardware system components actions, to control and monitor environmental conditions and to design experiments with an extremely high level of flexibility. Scheduling assistant with calendar function allows running multiple experiments simultaneously provides scheduling treatment per sample or group of samples with different experimental protocols and sample handling regimes including dark/light adaptation and pipetting schemes.

All acquired imaging data are stored in an SQL database, processed and available for inspection and further analysis in range of seconds after recording via user-friendly graphical interface. PlantScreenTM Data Analyser provides tools for data browsing, grouping, analysis, user-defined reprocessing and export. Multiple clients can be connected to the database, with different privileges assigned based on a built-in authentication mechanism. An SMS and mail notification service is integral part of the complete phenotyping system. 24-hour online support service is key component of the PlantScreenTM phenotyping solution.

Key features of IT solution

- Comprehensive software package for system control, data acquisition, image analysis and data base configuration

- Species-specific analysis

- Open database structure

- Remote access

- Automatic SMS and email notification service

- 24-hour online support service

- Online environmental monitoring

Online monitoring

Over past two decades PSI has pioneered numerous techniques for non-invasive measurements of algal physiological processes, which have been integrated into our unique line of PlantScreenTM phenotyping systems and optimized for the controlled environment. A comprehensive PlantScreenTM Software package, with remote accessibility allow users to remotely control all aspects of the system – from checking the actual state of measuring round to data browsing.

The system is modular and designed so that additional features may be added as the user´s screening requirements evolve.

Specific imaging sensors are implemented in robot operated stations. These non-invasive algae imaging technologies were developed to study different aspects of algae growth and physiological performance. Processed data can be browsed online during experiment.

Sensor available for the AlgaeScreen:

- Kinetic chlorophyll fluorescence Imaging

- Hyperspectral Imaging in visible region

Other instruments from 3rd party manufacture, that are suitable for robotic automatization can be added to the system (flowcytometer, centrifuge..). For more info, please contact PSI.

All data acquired from imaging sensors are in raw format and processed format stored in an SQL database and are in the range of minute after recording available for further analysis. All raw and processed data files are directly accessible and therefore can be easily analyzed by user-defined processing scripts.

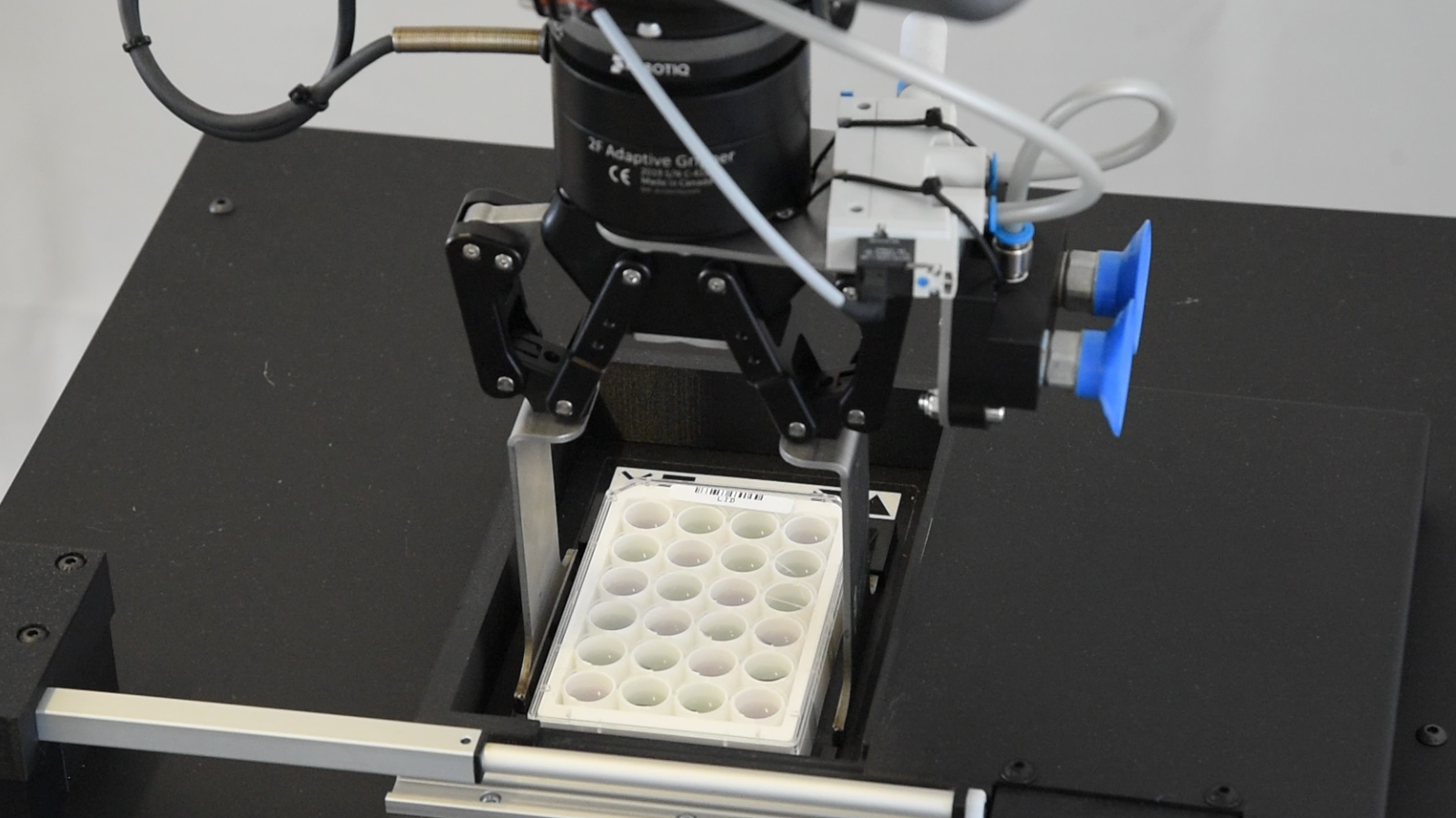

Sample preparation

AlgaeScreen can be equipped with sample preparation stations. Storage is a user and robot-operated station that can store reservoirs with media or samples, tipracks or microplates. But Heart of sample preparation is fully integrated pipetting robot that can be autonomously operated by robotic arm. This Liquid handling station have slots for two pipettes – single or multichannel (depends on customer configuration). Single channel pipette can be in range from 1µl to 1000 µl, multichannel in range 1-300 µl.

Liquid handling station has custom-made desk with 10 positions on that can be used for microplates, reservoirs, tuberacks and tipracks. One position can be equipped with a magnetic stirrer to provide homogenous mixture of reservoir during pipetting. Pipetting protocols are custom-made and fulfill all customers requirements.

Kinetic chlorophyll fluorescence Imaging

Chlorophyll fluorescence is popular technique in plant physiology used for rapid non-invasive measurement of photosystem II (PSII) activity. PSII activity is very sensitive to range of biotic and abiotic factors and therefore chlorophyll fluorescence technique is used as rapid indicator of photosynthetic performance of plants in different developmental stages and/or in response to changing environment. Systems developed by PSI monitor fluorescence kinetics in pulse-amplitude modulated mode, which provides a wealth of information about a plant’s photosynthetic capacity, physiological and metabolic condition, as well as its susceptibility to various stress conditions.

The advantage of chlorophyll fluorescence measurements over other methods for monitoring stresses is that changes in chlorophyll fluorescence kinetic parameters often occur before other effects of stress are apparent. The method is non-invasive, and the spread of inhibition can be observed and quantified with time. Heterogeneity in the location of inhibition is easily seen and quantified when using imaging systems to measure chlorophyll fluorescence. Chlorophyll fluorescence kinetics measured in the AlgaetScreenTM Phenotyping Systems provides a wealth of information about a plant’s photosynthetic capacity, physiological and metabolic condition, as well as its susceptibility to various stress conditions.

Key features

- High sensitivity CCD camera

- Multi-colour LED light panel

- Pulse-modulated short duration flashes for accurate measurement of minimal fluorescence (Fo value) determination

- Two types of actinic lights for light-adapted and quenching analysis with maximum light intensity reaching 2000 µmol.m-2.s-1.

- Saturating light pulse for maximal fluorescence Fm value determination with maximal light intensity up to 6000 µmol.m-2.s-1

- Additional light: FAR (735 nm) for determination of Fo'. Royal blue (450 nm) as excitation light source for GFP detection.

- Camera includes 7 position filter wheel, ChlF and GFP filter and other filter sets according to user’s needs.

- User defined programmable measuring protocols.

- Automatic data analysis and parameters computation

Hyperspectral camera

Hyperspectral camera integrated in AlgaeScreen is measuring samples in transmission mode from bottom side of plates. Camera can measure full spectral scan in visible (VNIR) spectra for each pixel of image. For monitoring of growth or pigment composition absorbance in specific wavelength like 480nm,680nm or 720 nm can be automatically analyzed. Also many different user-defined indices can be visualized using PlantScreenTM analysis software.

The camera is mounted on opposite side then LED light sources that is adjusted for homogenous sample illumination and is working linescan mode.

Key features

- Spectral range covers wavelengths from 380 to 900 nm

- Transmission mode scan

- Automatic calibration

- Automatic analysis of defined parameters

- Linescan operation